Hear your ideas.

Improved working environment while reducing environmental impact

A newly imagined eco-friendly spot cooler that cools with the power of water and wind

In recent years, rising temperatures due to global climate change have had a variety of effects. The Paris Agreement, an international treaty for combating climate change, has set the reduction of CO2 and other greenhouse gases emissions as a common global target. In Japan, rising summer temperatures have increased the risk of heatstroke, which can be fatal. Companies are expected to balance reducing CO2 emissions while coping with the heat.

Brother confronted this challenge and developed an energy-saving spot cooler that cools with the power of water and wind. These coolers are sold through the group companies, BROTHER SALES, LTD. and BROTHER ENTERPRISE, LTD.

Energy-saving cooling technology—Brother’s efforts to create environmentally friendly products

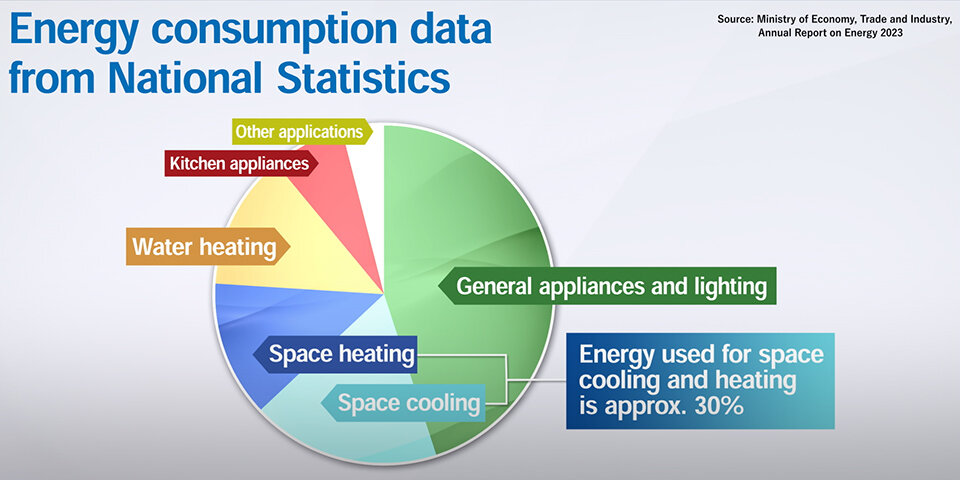

Energy Consumption Intensity by Tertiary Industry Use in Energy White Paper 2023, Ministry of Economy, Trade and Industry.

Brother is making an effort to reduce its CO2 emissions as part of its goals for the Brother Group Environmental Vision 2050 announced in 2018, and this includes contributions through its products. The majority of CO2 emissions worldwide originate from fossil fuel combustion used for power generation. Therefore, developing highly efficient, energy-saving, environmentally friendly products and reducing energy use (power consumption) at our customers’ sites will lead to a reduction in CO2 emissions for society as a whole. According to national statistics*, the majority of energy consumed in society is in the business sector. From this, air-conditioning takes up about 30%, second only to power for equipment and lighting, which is at 46%. Brother knows that with global warming on the rise, the need for low energy consumption cooling would grow. That is why we decided to develop an eco-friendly cooling system as a new business.

*Source: Ministry of Economy, Trade and Industry, Energy White Paper 2023

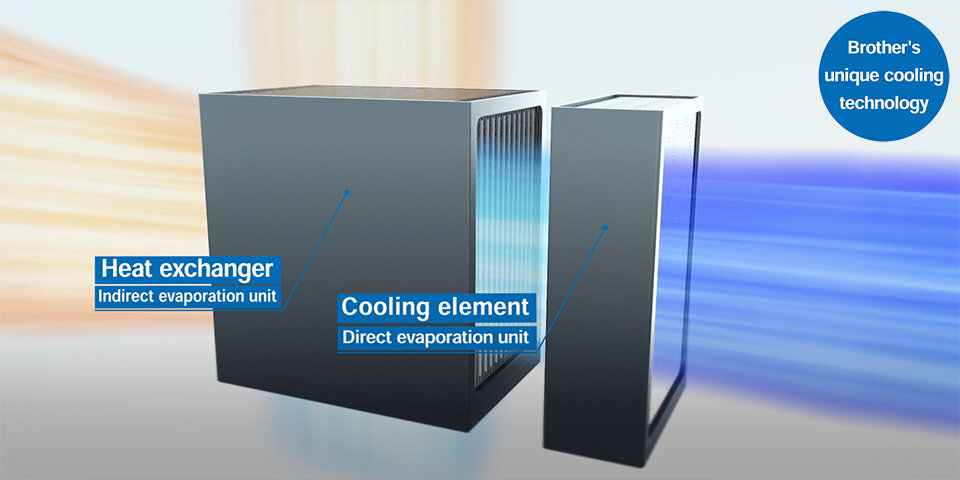

Two-stage cooling technology that focuses on the heat of vaporization of water

Conventional cooling systems are generally heat-pump types, in which a compressor compresses a refrigerant gas and releases heat to produce a cool breeze. Although the cooling performance is high, it requires a lot of electricity and generates a lot of heat exhaust at the same time as the cool breeze. In addition, the fluorocarbons used as a refrigerant have a high greenhouse gas effect and are subject to worldwide reduction policies. Brother focused on utilizing water’s natural cooling effect which draws a great amount of heat from its surroundings to evaporate. Although evaporative coolers also make use of this ability, their cooling element has limited cooling capacity. Therefore, we developed our special two-stage cooling technology that uses the same cooling element in its direct evaporation unit but is paired with indirect evaporation unit placed inside a heat exchanger.

Development of the environmentally friendly spot cooler

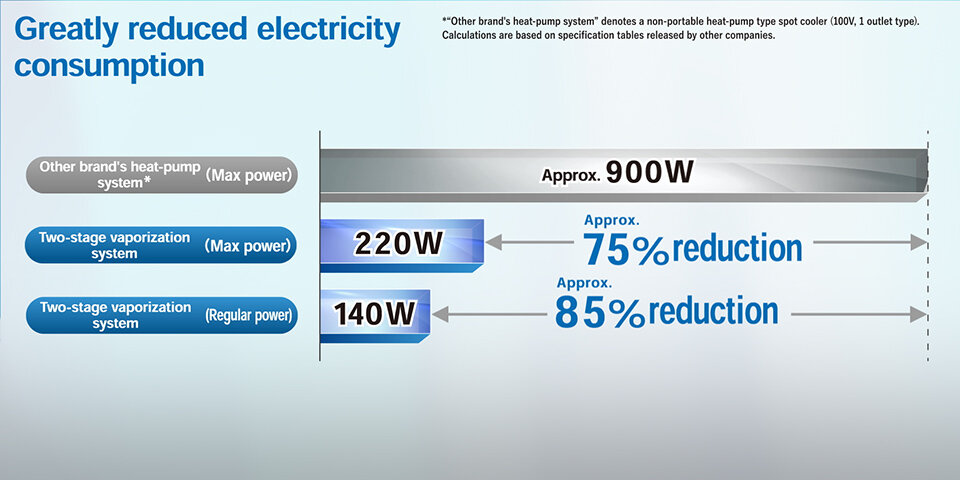

We used this technology in our spot coolers deployed on-site. In recent years, as the global average annual temperature has been rising, heatstroke has been occurring more frequently in warehouses, factories, and other workplaces during the summer. Unlike offices, which are designed for many employees to gather and work together, in warehouses and factories the density of workers is extremely low in relation to the vast space. This makes air-conditioning the whole area inefficient from an energy standpoint. In such an environment, spot coolers are useful to create a comfortable workspace by supplying cool air to individual workers. However, spot coolers are mainly the heat-pump type, and when Brother’s developers went around to interview users on-site, they received complaints about the heat exhaust that was generated at the same time as the cool breeze, as well as the weak airflow. Therefore, we developed spot cooler using two-stage cooling technology and succeeded in creating a cool breeze without generating heat exhaust, while consuming less than approximately one quarter of the power of a regular heat-pump type spot cooler. Furthermore, the powerful airflow also achieves a lower sensible temperature.

Expanding lineup and positive recognition

On the left: Model for industrial vehicles, On the center: Stationary model, On the right: model for forklift. trucks

The completed spot coolers are already being used on manufacturing and distribution lines as well as at train and bus stations and event venues, among other places. It is leading the way to a better working environment. We also developed spot coolers for forklift trucks in response to Toyota Motor Corporation’s request for a heatstroke prevention measure for forklift operators. Our collaboration with Toyota Motor Corporation let us create prototypes and run field trials. Furthermore, we also developed a more compact model for industrial vehicles that can be used not only for forklifts but also for towing vehicles. In the Energy Conservation Best Products and Business Models category of the Energy Conservation Grand Prize sponsored by The Energy Conservation Center, Japan, its environmental performance has been recognized, with the model for forklift trucks winning the Prize of the Chairman of ECCJ in 2021 and the model for industrial vehicles winning the Prize of Director-General of Agency for Natural Resources and Energy in 2023. Brother uses environmentally friendly technologies to support industries and create safe working conditions while also cutting down on energy costs and CO2 emissions, making our own contributions to the SDGs in various ways.

“SDG Goal 8,” “Decent Work and Economic Growth,” includes target 8.8 to “promote safe and secure working environments.” “SDG Goal 9,” “Industries, Innovation and Infrastructure” includes target 9.4 to adopt “environmentally sound technologies and industrial processes” to achieve sustainable economic growth. In addition, SDG Goal 13, “Climate Action,” calls for “urgent action to combat climate change and its impacts.” Brother has improved the on-site working environment during the summer by scaling up the introduction of energy-saving spot coolers equipped with two-stage cooling technology. We will also contribute to the achievement of the SDGs by saving energy consumption for air conditioning in factories and distribution sites where spot coolers are used, thereby helping to reduce CO2 emissions.

Share this article on social media

Learn about this initiative's SDGs

In ”SDGs at a Glance,” the 17 goals of the SDGs are explained in easy-to-understand illustrations. Click on the goal you are interested in, and you can read about it in under a minute. Let's take a look at the SDG goals featured in this article.

Related Topics