Hear your ideas.

From Reducing EPS to Eliminating EPS

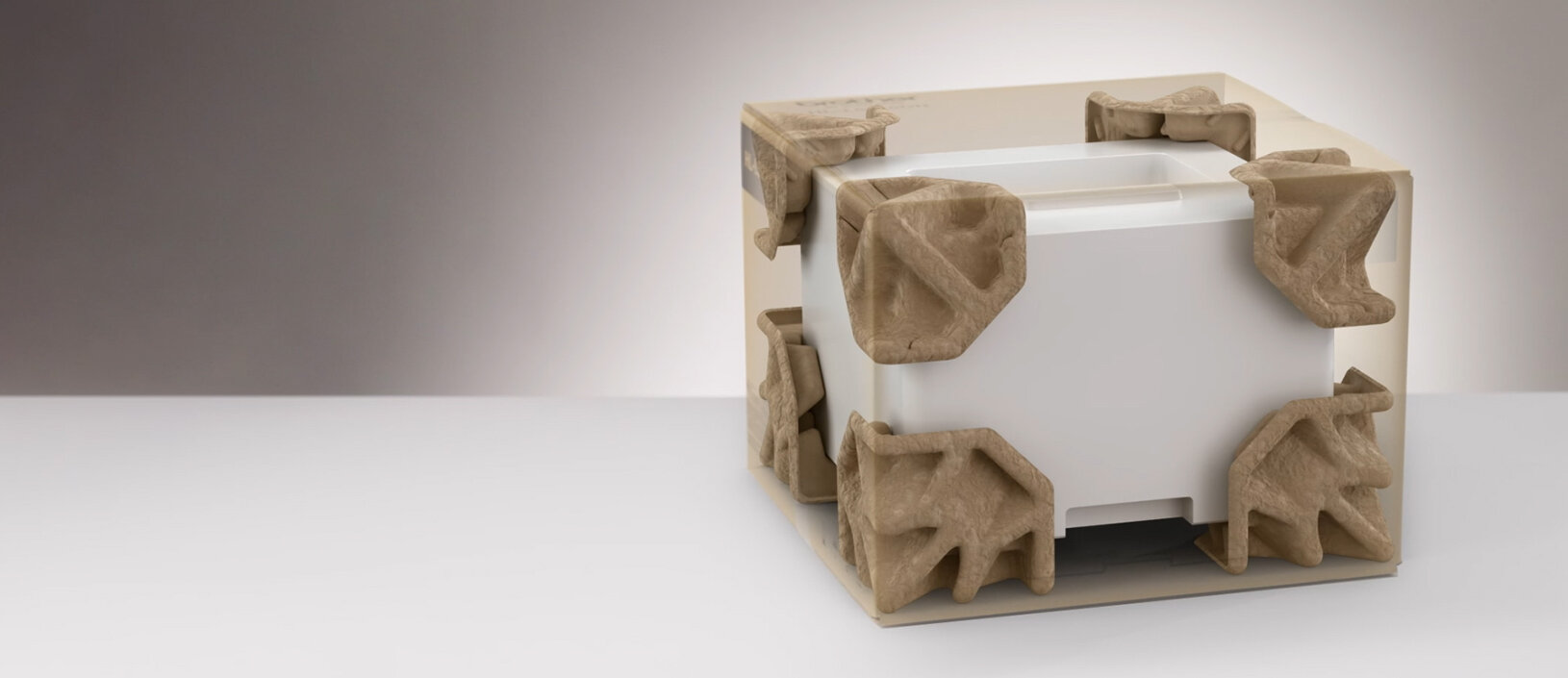

A sustainable cushioning material born from innovation

Brother products manufactured at our factories are transported to customers around the world by various means, including ships, airplanes, and trucks. It is the packaging materials that protect these products from the vibrations and shocks that occur during these logistics processes. Among these packaging materials, the key to performance lies in the cushioning material. It secures the product inside the cardboard box to prevent it from moving, and when subjected to impacts such as drops, it absorbs the shock by deforming itself, thereby protecting the product from damage.

At Brother, we have traditionally used expanded polystyrene (EPS), which offers excellent performance while conserving resources, as cushioning material. However, aiming to reduce marine pollution and ecological impact caused by plastic waste and to promote sustainable resource use, we have developed cushioning materials made from paper and have begun replacing conventional materials with them.

Efforts to reduce environmental impact with EPS

Under our Brother Group Environmental Vision 2050, which looks ahead to the year 2050, we aim to maximize resource circulation to ensure the sustainable use of resources and to minimize the environmental impact due to wastes. One of the target areas in this initiative is packaging materials.

For packaging materials, Brother has long used environmentally friendly and easily recyclable cardboard for outer boxes. As for cushioning materials, we have traditionally used plastic-based EPS, which offers excellent cushioning performance, to ensure that products are safely delivered to customers. At the same time, we worked on a reducing EPS initiative to minimize the amount used. By downsizing as much as possible while maintaining sufficient rigidity, we sought to reduce the production and disposal of plastic. This approach was based on the belief that EPS, with its excellent cushioning properties, could deliver high performance with minimal resource use and that, if properly collected, disposed of, and treated, it could mitigate its environmental impact.

Accelerating new cushioning material development due to marine plastic pollution

However, as global marine pollution caused by improperly managed plastic waste and its serious impacts on ecosystems became increasingly evident, momentum for plastic-free initiatives grew worldwide. Estimates suggest that about eight million tons of plastic waste flow into the ocean annually, and it is projected that by 2050, the weight of plastic waste in the oceans will surpass that of fish.* Facing this stark global reality, Brother recognized the urgent need to shift from reducing EPS to eliminating EPS and accelerated the development of new cushioning materials that could replace EPS while exerting less environmental impact.

*Source: Ministry of the Environment, Government of Japan, "Annual Report on the Environment, the Sound Material-Cycle Society and Biodiversity in Japan 2019"

New simulation technology for sustainable cushioning materials

While PET (polyethylene terephthalate) materials, which are highly resistant to humidity and easily recyclable, were considered for the new cushioning material, we ultimately chose molded pulp made from recycled paper to align with our plastic-free goals. At the time, Brother had no expertise in designing molded pulp cushioning materials. Therefore, while we initially outsourced the design to packaging manufacturers, we also decided to design the product and packaging as an integrated unit in-house, aiming to further conserve resources and reduce CO2 emissions. To streamline this design process, we began developing simulation technology capable of accurately predicting how molded pulp would deform under impact. Since no established methods existed at the time, we started by observing and analyzing existing molded pulp cushioning materials. By applying in-house expertise and conducting repeated trials, we continued verification work. Eventually, we succeeded in reproducing actual deformation patterns through simulation—achieving this in just about a year from the start of development.

Innovation brought by new technology

Utilizing this proprietary simulation technology, Brother designed new cushioning materials made from molded pulp. Through more than 100 rounds of analysis, we pursued a lighter, more compact, and resource-efficient design. As a result, we achieved a 33% weight reduction in cushioning materials compared to the initial designs, contributing to CO2 emission reductions. Additionally, some products achieved a 7% reduction in box size compared to when EPS was used, thanks to the more compact cushioning design. The new Brother cushioning materials with their highly versatile shapes which are crafted through these processes, are easy to apply across a wide range of products. Furthermore, their stackable design enables efficient storage and transportation by saving space. This cushioning material has earned high acclaim both in Japan and internationally, winning the Technical Packaging Award at the Japan Packaging Contest 2024 hosted by the Japan Packaging Institute and the WorldStar Award at the WorldStar Global Packaging Awards 2025 hosted by the World Packaging Organisation. Brother will continue to leverage this technology to further pursue resource-efficient cushioning materials, expand their adoption across more products, and engage in manufacturing that contributes to a sustainable society.

Sustainanble, Compact, and Lightweight Packaging (Figures in the video are as of May 2025)

SDG Goal 12, "Responsible Consumption and Production," aims to ensure sustainable consumption and production patterns, including the target (12.5) to "substantially reduce waste generation through prevention, reduction, recycling, and reuse." The use of sustainable cushioning materials made from molded pulp contributes to this goal by reducing waste generated in homes and offices and promoting recycling, thus helping to build a more sustainable society.

Share this article on social media

Learn about this initiative's SDGs

In ”SDGs at a Glance,” the 17 goals of the SDGs are explained in easy-to-understand illustrations. Click on the goal you are interested in, and you can read about it in under a minute. Let's take a look at the SDG goals featured in this article.

Related Topics